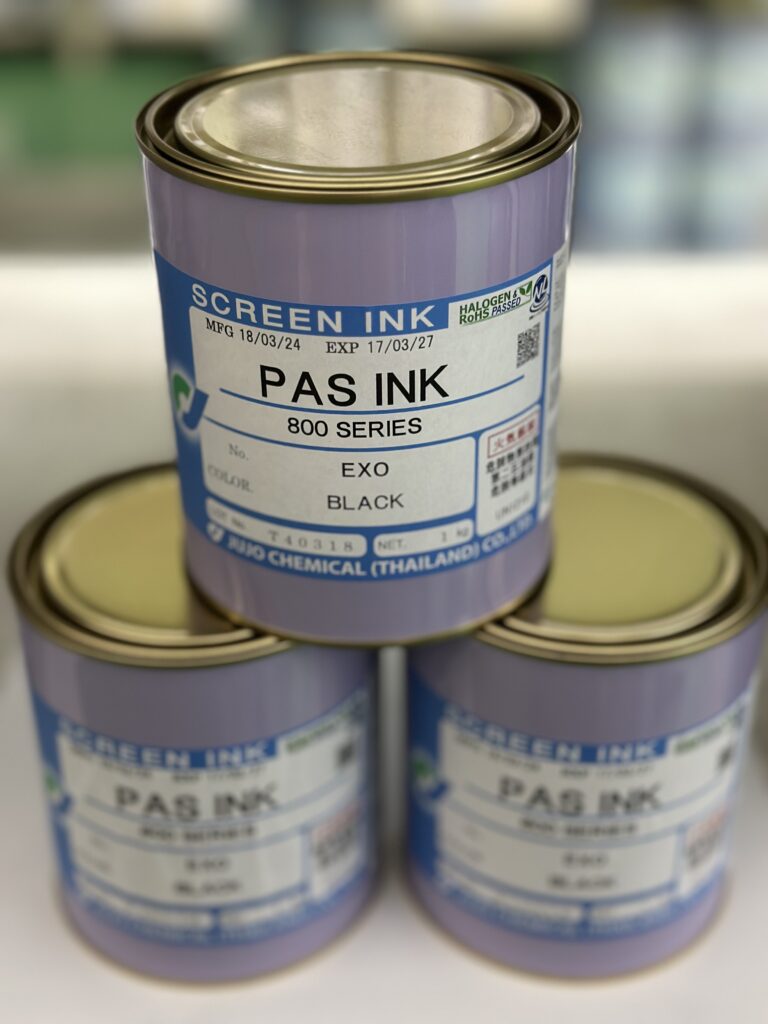

800 SERIES PAS INK

Properties

Low odor. No cracking on substrates. Excellent physical properties.Styrene(PS), HI-PS, AS, Acryl, ABS.

INTRODUCTIONS

PAS INK is designed for the substrates whose solvent-resistance is weak(styrol, hi-impact styrol or AS). The finish is gloss.

APPLICATIONS

Styrol, hi-impact styrol(HIPS), AS, ABS, acryl.

CHARACTERISTICS

Good printability. Low odor.

Good adhesion. No cracks are caused on the substrates.

Excellent hardness and impact resistance.

Excellent in resistance to heat, coldness and weathering. Good durability.

HOW TO USE

Dilute the ink with STYROL THINNER(fast drying, standard drying, slow drying) or #1 fast drying, #2 standard drying, #3 slow drying and #4 retarder. Proper thinner should be chosen depending on the substrates:

Styrol, HIPS, AS : STYROL THINNER

Acryl, ABS : #1, #2, #3, #4

DRYING

Ink dries at room temperature. However, as it takes time for the ink to adhere to the substrates when dried at room temperature, forced drying is recommended.

STENCIL & WASHING UP

Use photo-stencil. Use VINYL CLEANING THINNER for washing up.

LIGHTFASTNESS

5-8 grades (Please refer to lightfastness chart).

COLORS & TYPE OF PACKING

Standard 20 colors, EXO(extra opaque) 8 colors. 1kg can

PRECAUTIONS

1. The alcohol resistance of PAS INK is not good.

2. PAS INK may not pass the specifications of automobile meters/name plates made of polycarbonate and acrylic resin. 8000 SERIES PC INK or 8100 SERIES SNAP INK is recommended for these applications.

3. Please refer to MSDS before use.

4. Be sure to do trial print before commercial run to confirm that the product fits the purposes.

Applications Usage

Styrene(PS), HI-PS, AS, Acryl, ABS.