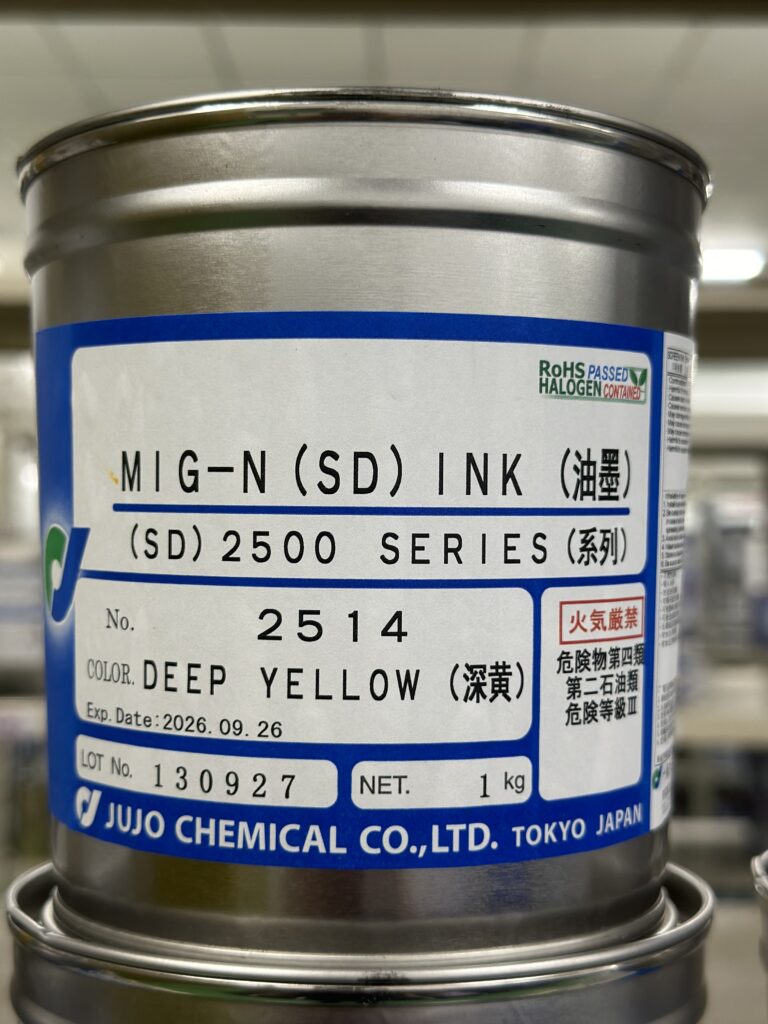

2500(SD) SERIES MIG-N INK

Properties

Excellent adhesion. Chemical resistance.Boiling & alcohol resistance.

INTRODUCTIONS

2500 SERIES MIG-N(SD)INK is one-pack type of ink designed for metal and glass. 2500 SERIES MIG-N(SD)INK is slow drying version of conventional 2500 SERIES MIG-N INK. Its adhesion to the materials is superb and the physical properties and weathering resistance are also excellent.

APPLICATIONS

Unprimed-metal, primed metal, glass, ceramics, thermo-setting resin products.

CHARACTERISTICS

– Excellent adhesion and glossy finish.

– Ink film is tough. Superior physical properties and weathering resistance can be obtained.

– Ink cures at relatively low temperature(150°C)(302°F).

– The possibility of clogging is low due to its slow drying.

HOW TO USE

1. It is easy to handle compared with two-pack type of ink which has pot life.

2. Dilute the ink with TETRON THINNER or PC THINNER.

3. Add thinner by 10-20% and stir well before printing.

DRYING

Tack-free-level of drying can be obtained with hot wind drying at 50°C(122°F) for 7 minutes plus 100°C(212°F) for 2 minutes. Dry each color under these conditions before printing other color on top of it. Baking should be done only once after printing the last color. Baking conditions : 150°C(302°F) x >30 minutes.

STENCIL AND WASHING UP

Use photo-stencil. Our VINYL CLEANING THINNER is recommended for washing up.

COLORS & TYPE OF PACKING

Standard 13 colors, Halftone 5 colors. 1-kg-can

PRECAUTIONS

1. 2500 SERIES MIG-N(SD)INK reacts to heat. Store the ink at low temperature (<40°C)(<104°F).

2. This ink does not cure unless it is heated at the higher temperature than 150°C(302°F).

3. Add JA-1000 by 0.5-1% when printed on glass. Adhesion and physical properties such as solvent resistance are much improved. Pot life of the mixture is 12 hours at 20°C(68°F).

4. Please refer to MSDS before use.

5. MIG-N is manufactured after receiving order. There is no stock.

6. Be sure to do trial print before commercial run to confirm that the product fits the purposes.

PHYSICAL PROPERTIES

| Test items | Test methods | Results |

|---|---|---|

| Adhesion | Cross-hatch, tape-peeling test | 100/100 Passed |

| Hardness | JIS K5400.8.4 pencil hardness | 3H-4H |

| Impact resistance | JIS K5400 8.3.2 Du Pont Impact Tester 1/2 inch, 500 grams, 20 cm |

No cracks, No peeling |

| Solvent resistance | 1. Lacquer thinner – rubbing (MIBK/Ethylacetate/Toluen=1:1:1) |

>100 times |

| 2. Xylene – rubbing | >100 times | |

| 3. Methanol – rubbing | >200 times | |

| 4. Immersion in gasoline, 1 hour | Passed | |

| Abrasion resistance | 1000 times with cotton cloth | Passed |

| Heat resistance | JIS K5400 8.13 180°C(356°F), 30 minutes | Passed |

| Coldness resistance | -30°C(-22°F), 48 hours | Passed |

| Water-proofness | JIS K5400 8.19. Immersion in water(40°C)(104°F), 14 days | Passed |

| Humidity resistance | >95%, 50°C(122°F), 14 days | Passed |

| Boiling water resistance | Immersion, 1 hour | Passed |

| Detergent resistance | Immersion in 5% detergent, 24 hours | Passed |

| Oil resistance | Immersion in motor oil, 24 hours | Passed |

| Cleaner resistance | Immersion in cleaner, 6 hours | Passed |

| Alkali resistance | Immersion in 5%NaOH, 6 hours | Passed |

| Acid resistance | Immersion in 5% H2SO4 , 6 hours | Passed |

| Salt-water resistance | Immersion in 5%salt water, 14 days | Passed |

| Weathering resistance | Sunshine Weather Meter, 1000hours | Passed |

- Immersion test was performed at room temperature.

- The different results may be obtained depending on substrates.

- Weathering resistance depends on the color. Please refer to lightfastness chart.

- The above information were gained by our laboratory testing and no guarantee is implied

Applications Usage

Excellent adhesion. Chemical resistance.

Boiling & alcohol resistance.