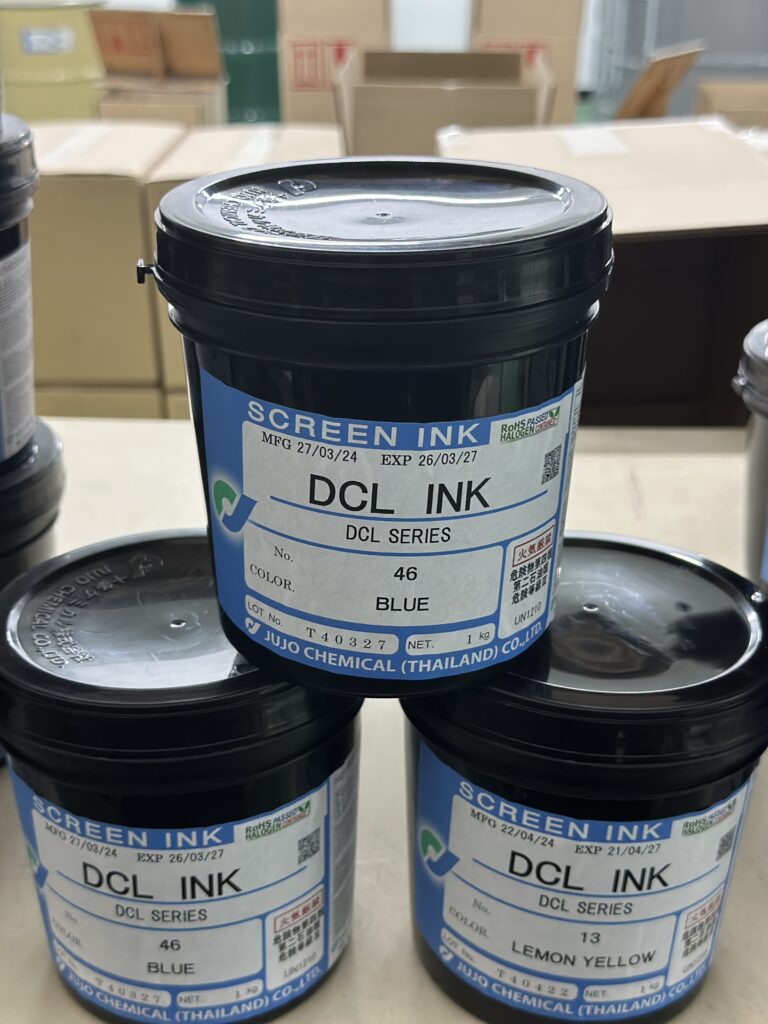

DCL INK

INTRODUCTIONS

DCL INK with gloss finish has superior weathering resistance.

DCL is designed for the applications that need excellent weathering resistance such as automobile sticker. Weathering resistance and gloss are even more improved with DCL , OCC.

APPLICATIONS

Printing on weathering resistant vinyl sticker , Vinyl-chloride-resin-decorative steel sheet , flexible vinyl , rigid vinyl, ABS , polycarbonate , PVC

CHARACTERISTICS

– Superb weathering resistance (SWOM > 300H outdoor exposure > 2 years

– Clogging is hard to happen and printability is excellent.

– Excellent resistance to alcohol , gasoline , oil and chemicals.

– Flexible and blocking-resistant.

– Harmful substances such as heavy metal are not Contained.

HOW TO USE

Dilute the ink with PC thinner (slow drying , retarder , special retarder). Use Vinyl Cleaning Thinner for washing up. 150-250 meshes/inch is recommended.

XN-14710 (KAI) : Hardener JA-950 = 100:25 is mixing ratio. Dilute the mixture with PC thinner (slow drying , retarder , special retarder). Use Vinyl Cleaning Thinner for washing up. 150-250 meshes/inch is recommended.

Pot life of the mixture is 3-4 hours at 20 degrees Celsius.

Drying

Ink dries at room temperature although drying time varies depending on the substrate.

Ex. Complete drying time when diluted with PC thinner standard drying by 20% (room temp. 20 degrees Celsius)

vinyl sticker , flexible vinyl : 10-20 min.

polycarbonate , rigid vinyl : 20-60 min.

Drying time is shortened by forced drying such as with the jet dryer.

Heat drying conditions are 80 degrees Celsius x 60 min. Ink almost dries at room temperature after 24 hours , but drying completes after 3-4 days. The properties obtained at room temperature are inferior to what obtained with heat drying.

Weathering Resistance

7-8 grade. Please refer to “Lightfastness List ” for the information of each color.

Color Range and Type of Packing

standard 14 colors , XN-14710 (KAI) 1-kg-can

Precautions

Please refer to MSDS before use.

Properties

Three hits on polycarbonate

Printing sequence : 38 red → 90 black → super white

Diluted with PC thinner standard drying , polyester 225 meshes/inch

| TEST ITEMS | TEST METHODS | RESULTS |

|---|---|---|

| Adhesion | Cross-hatch + tape-peeling | 100/100 NO feel-off |

| Impact resistance | JIS K5400 8.3.2.DuPont impact Tester 1/2 inch, 500g, 50cm | No cracks , No peel-off |

| Pencil hardness | JIS K5400.8.4 Scratch test | HB |

| Heat resistance | JIS K5400 8.13 , 80°C(176°F) x 24 hrs | No change in the appearance |

| Cold resistance | -30°C(-22°F) x 24 hours | No change in the appearance |

| Water-resistance | JIS K5400 8.19 , in (30°C)(86°F) water x 24 hrs | No change in the appearance |

| Humidity resistance | (40°C(104°F) x Humidity 95% RH x 16 hrs –> room temp. 8Hr) x 3 cycles | No change in the appearance |

| Heat-cold cycle | 4 cycles of below conditions (*1) | No cracks , No peel-off |

| Solvent resistance | 50 rubs with 99% ethanol or methanol | No change in the appearance |

| Blocking resistance | Face-to-face 10 cm² , with 2kg at 50°C(122°F) x 60min. | No blocking |

| Abrasion resistance | 100 rubs with eraser | Scarred but no peel-off |

| Weathering resistance | Sunshine Weather-O-Meter, 3000 Hr | No change in the appearance of all colors |

| Outdoor exposure at 40° to the south for 2 years | No change in the appearance of all colors |

(*1) 100ºC x 2.5Hr → room temp. x 1Hr →

-30ºC x 2.5Hr → room temp. x 2Hr (total 8 Hr) = 1 cycle

Notes

1) The information given here is based on our laboratory testing and is no guarantee.

2) Weathering resistance remarkably changes depending on the ink thickness and how the printed matter is used. The above information is obtained with dark color. The properties of pale color are inferior to those of dark color.