RC GA 41 Series

Properties

Fast curing. Excellent in hardness, physical & chemical properties.

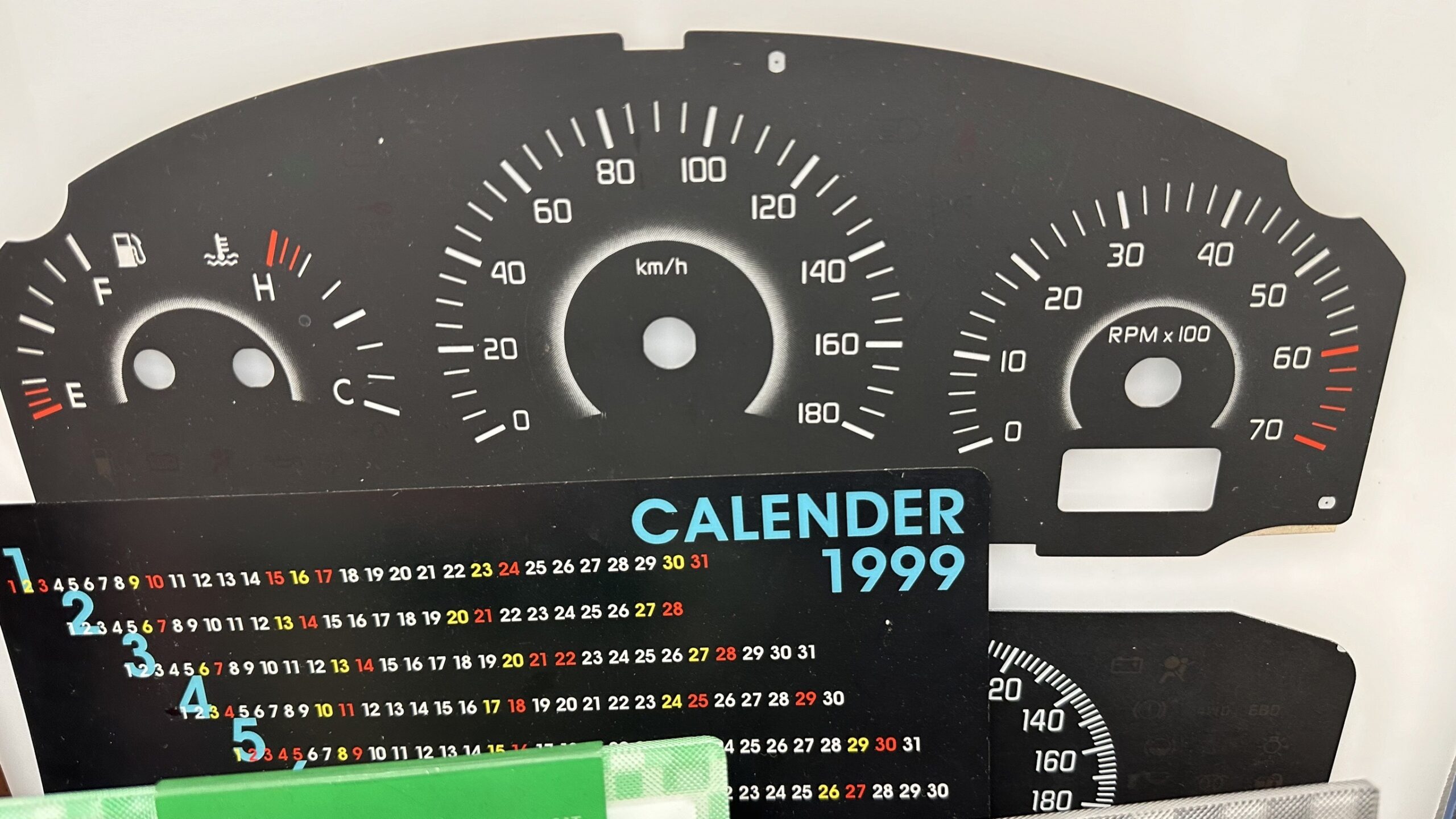

Polycarbonate (PC). Rigid PVC. ABS.

INTRODUCTIONS

RC GA 41 SERIES is UV curable gloss ink with hard ink film and chemical resistance.

APPLICATIONS

Polycarbonate, PVC stickers, rigid PVC, treated PET films, AS, ABS, acryl(injections).

CHARACTERISTICS

Excellent curing and adhesion.

Stable on the screen and good reproducibility.

High gloss and transparency.

High gloss and transparency.

Low skin irritation(P.I.I<2.0). Safe to handle.

COLOR RANGE

COLORS

WHITE, OPAQUE WHITE, LEMON YELLOW, YELLOW, DEEP YELLOW, ORANGE, BRIGHT RED, RED, GERANIUM, PINK, VIOLET,

DEEP BLUE, BLUE, MARINE BLUE, GREEN, BLACK

CLEAR

1. 41-00 CLEAR

Compatible with gold and silver powder. To adjust viscosity. For various over-coating, High-gloss and good levelling.

2. 41-00 TRANSPARENT CLEAR

Good transparency. Non-silicone.

3. 41-00 MATT CLEAR

For pseudo-etching effects and non-glare printing. High thixotropy. Good reproducibility of mesh pattern.

4. 41-00 TRANSPARENT MATT CLEAR

For pseudo-etching effects and non-glare printing with transparency. High viscosity and transparency.

5. 41-00 HFT MATT CLEAR

Flat and matt finish

6. 41-00 DP-1 CLEAR

Coarse textured surface. Good scratch resistance.

7. 41-00 UF-1 CLEAR

Finer version of DP-1.

8. 41-00 UB-1 MATT CLEAR

Fine textured surface(high density)

9. 41-00 UB-2 MATT CLEAR

Fine textured surface(low density)

10. 41-00 RL-A RELIEF CLEAR

For relief print. Ink film is hard and suitable for thick substrate.

11. 41-00 RL-B RELIEF CLEAR

For relief print. Ink film is relatively soft and suitable for thin substrate.

12. 41-00 RL-C CLEAR

For braille points. Ink film is hard and suitable for thick substrate.

13. 41-00 RL-D CLEAR

For braille points. Ink film is relatively soft and suitable for thin substrate.

HOW TO USE

1. Ink is supplied in ready-to-use condition. Stir well before use.

2. Add 41-00 REDUCER up to 10%, if necessary.

3. Standard curing conditions: (These conditions change depending on the substrate.)

One metal halide lamp 120W/cm, Distance from focus : 10cm

Conveyor speed : 10m/min (Integral light : approx. 250mJ/cm²)

4. Mesh : 300-350 meshes/inch, Thickness of sol : <10 microns

PRECAUTIONS

1. Skin irritation(P.I.I.) of each color is low(under 2.0). However, it is advised to avoid skin contact. In case of skin contact, please wash with soap and water immediately.

2. Store the ink in a cool and dark place. Stir occasionally to keep stability when the ink is stored for a long time.

3. Hard ink film is the characteristics of GA 41 SERIES. When flexible ink film is required, use RC PF 42 SERIES, RC VX 47 SERIES or RC M 47 SERIES

4. Please refer to MSDS before use.

5. Be sure to do trial print before commercial run to confirm that the product fits the purposes.

COVERAGE

70-80m²/kg

PHYSICAL PROPERTIES

– Substrate : Polycarbonate sheet(thickness:0.5mm)

– Meshes : Polyester 300 meshes/inch(bias) Thickness of sol 10 microns,

– Thickness of printed ink film : 10 microns

– Curing : One metal halide lamp 120W/cm (Integral light : 300 mJ/cm²)

| TEST ITEMS | TEST METHODS | RESULTS |

|---|---|---|

| Adhesion | Cross-hatch, tape-peeling test | 100/100, Pass |

| Scratch resistance | Nail scratch | Excellent |

| Hardness | JIS K-5400 8.4 Pencil hardness | 3H |

| Over-printability | Adhesion test after 2-color-overprint | Excellent |

| Alcohol resistance | 100 double rubs with 100% alcohol | Pass |

| Gasoline resistance | 100 double rubs with gasoline | Pass |

| Solvent resistance | 100 double rubs with ethylacetate | Pass |

| HCl resistance | Immersion in 10% HCl for 24 hours | Pass |

| H2SO4 resistance | Immersion in 10% H2SO4 for 24 hours | Pass |

| Alkali resistance | Immersion in 5% caustic soda for 24 hours | Pass |

| Abrasion resistance | 300 double rubs with 500g/cm² load | Excellent |

| Weathering resistance | Sunshine weather meter-400 hours | Pass |

- Information given here is gained from our laboratory testing, and no firm guarantee is implied.

- Weathering resistance depends on the color. Please refer to lightfastness chart before use.

Applications Usage

Polycarbonate (PC). Rigid PVC. ABS.